Code Commentary

Intumescent Paints

Until July of 2015 intumescent paints or any other paints were not to be used as a protection of foamed plastics in accordance with the requirements set forth in the National Building Code.-Article 3.1.4.2 Protection of Foamed Plastic.

Article 3.1.4.2 allowed options for protection of SPF with interior finishes as outlined in 9.29.4 to 9.29.9. Sheet metal meeting specific requirements, or a thermal barrier that meets the requirements of sentence 3.1.5.12.

Historically, paints of any sort did not meet the requirements of the interior finishes, as they were not sheet metal, and they did not meet the requirements of a thermal barrier.

Intumescent paints have been used to meet US Code requirements as an ignition barrier. The Canadian 2010 National Building Code does allow an ignition barrier over foamed plastics as it does not conform to the prescribed performance as defined in the Canadian National Building Code.

The Canadian market currently has two paint products that have passed the required CAN/ULC S124-M – Standard Method of test for the Evaluation of Protective Coverings for Foamed Plastic. (figure 1.) Apendix A of the 2010 National Building Code states that the standard fire exposure temperature in CAN/ULC – S101-M – Standard Methods of Fire Endurance Tests of building Construction and Materials is the same as in CAN/ULC S124-M. A thermal barrier that, when tested in conformance with CAN/ULC S101-M will not exceed an average temperature rise of 140ºC on its unexposed face after a period of 10 minutes satisfies this requirement.

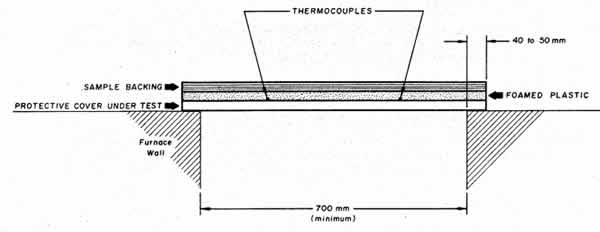

A thermal barrier can be described as a material which limits the speed by which heats transfers through a material. If you review the CAN/ULC-S124-M standard, you will see that essentially the material is installed over a furnace which produces a temperature of 704ºC. The protective coating is installed over a piece of foamed plastic with thermal couples between the thermal barrier and the foamed plastic. The specimen is placed with the thermal barrier exposed to the furnace. When the test commences, the furnace provides the 704ºC of heat and the temperature rise is measured over time between the thermal barrier and the foamed plastic. To be a class B thermal barrier the maximum temperature increase recorded shall be no greater than 140ºC when measured at the ten minute interval.

So if a thermal barrier is defined as a material which significantly slows the heat transfer through the material.

Fire in buildings is a serious health and safety issue. The spray polyurethane industry has spent countless hours and incurred much cost to ensure that spray polyurethane foam, properly installed, is a safe product to use in any construction type. The industry has included limitations in the CAN/ULC S705.1 Material Standard on flame spread when tested in accordance with CAN/ULC S102. Installers of spray polyurethane foam, when they are installing the material on the inside of a building, are required in CAN/ULC S705.2 to either install a thermal barrier or to inform the owner in writing that a thermal barrier is required.

Figure 1. Thermal Barrier Test Assembly

It is the responsibility of the AHJ to ensure that the building code requirements are met when approving the use of any products as an appropriate thermal barrier. When selecting an intumescent paint, the Contractor needs to ensure code compliance by reviewing the test results to confirm full compliance with the CAN/ULC S101-M or the CAN/ULC S124-M.

Update

The building code has not changed with regards to the prescriptive path to compliance when using approved thermal barriers over spray applied polyurethane foam insulation.

There are a number of acceptable products listed in the NBC and there are test protocols listed that, If passed, deem a product to be code compliant.

There is an approved thermal barrier material that is marketed as FLAME BLOC and FLAME SEAL that have passed the ULC S124M test and are listed on the ULC website.

Their test certificate(s) are available here:

Effective June 3rd, 2016, CCMC has issued a report on an Intumescent paint product known commercially as DC-315.

The report expresses an opinion of product use suitability that is limited to Part 9 buildings and has included details in their report. The decision to accept the product as an equivalent is left with the AHJ (Authority having Jurisdiction).

Please feel free to download the CCMC Report here:

All AHJ's are recommended to satisfy themselves as to the suitability of a thermal barrier material.

CUFCA shall update guidance as changes are made in the Canadian Marketplace.